Changes are in the air for the poultry and meat industry. It’s not a matter of if but when it seems. The Biden administration is in the process of re-regulating these industries due to their concern over Covid-19 breakouts and supply chain resiliency. This is a pretty big change from the previous administration’s deregulation push.

However, vaccines are now being distributed since these discussions started which would imply this is now a moot point. That doesn’t appear to be the case with our current administration. If they continue, could that leave meat processors to comply with rules that are potentially costly, overbearing, and outdated? The food industry gurus are advising with some warnings.

Food Industry – Planning for the Worse?

The food industry is taking note on the progression and at the virtual 2021 Annual Meat Conference Andrew Harig – Policy expert at FMI, the Food Industry Association, told those in attendance; “We’re gonna see a lot of new rules”.

More specifically, the meat industry should be prepared for changes surrounding supply chains, traceability, labeling and multiple other issues, experts say. Let’s discuss a few of these that are already in the works and why the industry feel changes are coming.

Supply Chains

On February 23rd, Biden issued an executive order on America’s supply chains requiring the secretary of agriculture to investigate supply chains for “agricultural commodities and food products.” By next year at the same time, officials must submit findings and recommendations to the president.

“Agricultural commodities and food products will be part of the second phase of the executive order and will be reviewed after one year with a report submitted on Feb. 24, 2022.” – Meat+Poultry

Note: Farmers will have an opportunity to comment on what’s good and bad about their supply chains this year as well. It will be interesting to see how that washes out.

Traceability

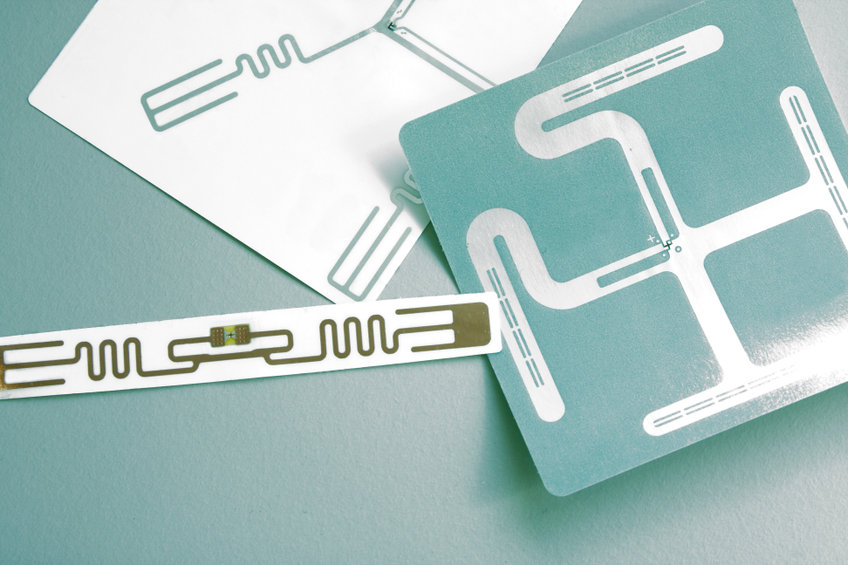

On September 23rd, prompted by section 204 of the Food Safety Modernization Act, the U.S. Food and Drug Administration issued a proposed rule on traceability. This is something I have talked about before. Serialization and Traceability

If adopted, the rule, called “Requirements for Additional Traceability Records for Certain Foods,” will require everyone along the meat supply chain to keep more detailed records. The agriculture industry, specifically farmers, would have much more data factors to track. Not everyone thinks this is attainable it turns out, however. Casey Gallimore, director of regulatory and scientific affairs at the North American Meat Institute, called the proposal “unworkable.” She is encouraging producers to contact the FDA.

Labeling

“Product of USA” and cell-cultured product labeling are also priorities for the new administration. According to Gallimore, FSIS is moving forward with rulemaking on “Product of USA” labels for meat and poultry.

Some producers want “Product of USA” only on products from animals that were born, raised and slaughtered in the U.S., while others say the label should apply if an animal was raised abroad and slaughtered domestically. This will most likely end up somewhere in the middle per Gallimore.

Note: FDA and FSIS are also crafting label requirements for cell-cultured seafood and meat.

Salmonella

A crack down on salmonella is most likely coming for producers. “I’d argue salmonella’s the biggest issue facing the industry today,” said Gallimore.

To be clear salmonella influence in beef is pretty low, so upcoming standards likely won’t be too burdensome on beef. With that said, FSIS will review the most recent 48 samples. Two or fewer positive salmonella samples would meet performance standards; three or more would fail.

When a company fails a salmonella test, it will be published in a public disclosure database — Gallimore calls it a “naughty list.” The poultry industry is already dealing with this.

In Summary

The meat and poultry industries are used to being regulated and have worked with these issues for years. With that being said, the costs this time could be prohibitive and with production already strained prices to the public could grow exponentially. Not a good thing for anyone. Cost savings need to be found.

Many processors, small and large, are using archaic methods to capture data still today. Spreadsheets, check off lists, clipboards and manually transferring data are prone to errors. Not ideal for today’s government demands and hurt the bottom line. To be able to easily integrate new labeling standards into this mix would be a major cost savings as well. To have a complete solution that covers quality assurance, quality control, and gathering environment data for powerful reporting would be indispensable. That is what Coolearth Software can do for you.

Give us a call to discuss the latest offerings we have that could help you with all your regulation requirements.